Learning the foundations of three-dimensional (3D) printing is incredibly beneficial. 3D printing is no longer a futuristic pipe dream. Industrial designers frequently utilize 3D printing to make prototype models to evaluate the form, function, and fit of their designs. And hobbyists (like you or I, can use 3D printing to bring our ideas to life.

This MakerHub article will teach you the basics of 3D printing so that you can turn your ideas into real tangible objects.

What exactly is 3D printing?

3D Printing, also known as additive manufacturing, is the act of creating a three-dimensional object from a computer design. 3D printers heat substances, typically plastic, to generate a layer on top of other layers, which stacks up in three-dimensional space.

A 3D printer operates on the X, Y, and Z-axes. The X-axis is the left-to-right movement. The Y-axis is the front-to-back movement. And the Z-axis is the upward and downward movement.

3D Printing History

Many believed that 3D printing could only exist in science fiction, but 3D printing has become more popular and is now used in many industries. Although 3D printing was introduced in the late 1980s, it did not receive widespread attention until the 1990s. But it was not until the early 2010s that 3D printing became affordable for the average consumer. Today, you can find various affordable 3D printers on Amazon.

What is the process of 3D printing?

3D printers are members of the additive manufacturing family and operate like a typical inkjet printer, except, of course, in 3D.

Modeling is the first step

Before manufacturing a 3D object, the model must be created using computer software. Object models are often designed by manufacturing software known as computer-aided design (CAD) programs. When the object model is finished, it is stored in stereolithography (STL) or additive manufacturing file (AMF) format.

You or the manufacturing company you work with need to verify the model file for errors during the modeling process. If ignored, these errors can result in defects in the printed object.

Printing

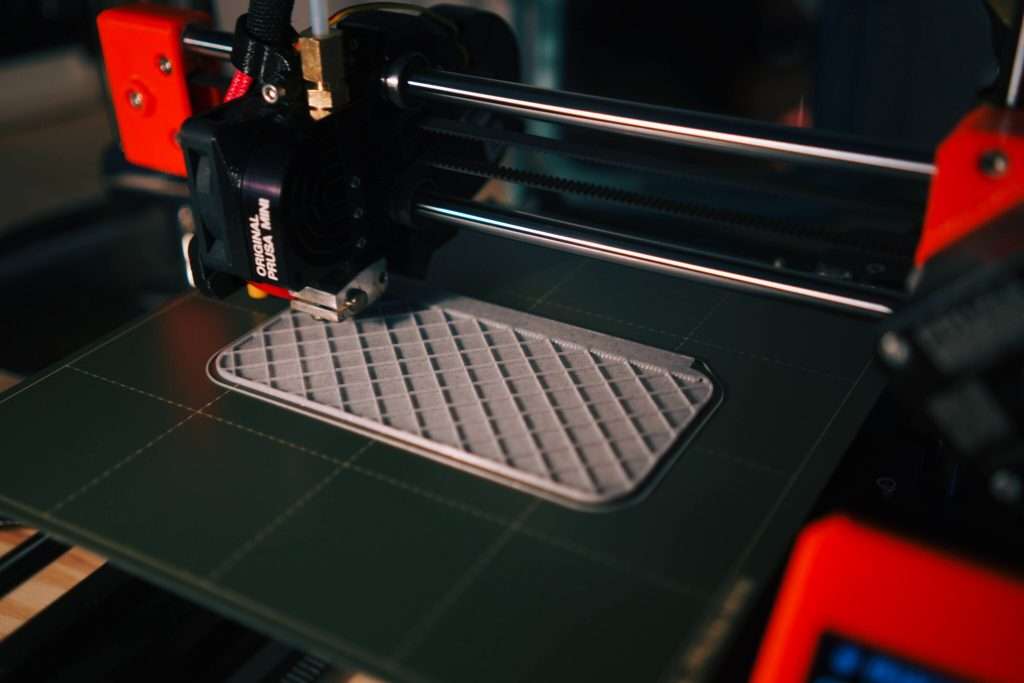

Assuming the STL or AMF file is error-free, the file will be uploaded to the 3D printer. The instructions in the corresponding file will be used by the 3D printer to determine where and how the material is deposited.

The majority of 3D printers construct objects by depositing layers of material onto a bed. The bottom layer will be built initially, followed by the next-highest layer.

To construct objects, 3D printers can employ a variety of materials, the most popular of which is thermoplastic.

Completing

Finishing is the third and last phase in 3D printing. Finishing, as the name implies, is the process of applying the final touches to a printed piece. Solvents, for example, can be applied to the printed product to remove any surface flaws while also producing a smoother surface finish. If supports were employed to hold the object during printing, they must be removed during this third and final stage.

3D printer classifications

There are various sorts of printers on the market. FDM, SLA, and SLS printers are the most common.

FDM printers are typically the most affordable solution for novices or homebrewing engineers. This is because they are simple to maintain, and the filament is less expensive than the other two types. However, clogged nozzles, laborious clean-ups, and striping are also disadvantages of FDM printers.

SLA printers use a liquid resin hardened by UV radiation to produce a product. These printers are excellent for fine details (down to 25 microns), but they cost several thousand dollars more than FDM printers. In addition, there are disadvantages of SLA printers, including clogged nozzles and material limitations.

Finally, there are SLS printers. SLS printers employ powder rather than liquid resin. These printers are the most expensive, typically costing more than $50,000. So, naturally, the most significant downside is the cost. However, it provides detail down to 16 microns and doesn’t require infill patterns to be stable.

Common terminology

Below is some common 3D printing terminology.

Additive manufacturing: The process of adding materials to create an object.

Bowden extruder: An extruder type for FDM printers that has a separated hot end and motor.

Computer aided design (CAD): The process of designing parts or objects in a digital environment.

Computer aided manufacturing (CAM): The process of using software to automate a manufacturing process.

Curing: Using UV light to solidify liquid resin.

Digital light processing (DLP): A printer that projects light across an entire layer of resin to cure it all at once.

Elephant’s foot: An error where the first layer is distributed wider than needed.

Extruder: An extruder is a motor with gears that feeds filament to the printer’s hot end.

Filament: A material cmmonly used in 3D printing.

Fused deposition modeling (FDM): A printing method where material layers are fused together in a specific pattern.

Hot end: Consists of a heating cartridge and a thermistor to heat the filament.

Infill: The interior of the printed object. Infill patterns may vary and help provide internal structure to the printed object.

International Organization for Standardization (ISO): A worldwide standard of quality.

Selective laser sintering (SLS): A 3D printing process that uses a laser to fuse a thermoplastic powder to build prototype parts.

Stereolithography (SLA): A type of 3D printer that uses a laser to cure liquid resin with high accuracy.

Striping: A common problem with FDM printers where individual layers become visible in the end product.

Thermoplastic: A plastic made of polymer resins that soften when heated and hardens when cooled down.

Vat Polymerization: A resin-based 3D printing where liquid photopolymer resin is stored in a vat.

Conclusion

So, are you ready to learn more about 3D printing? If so, check out all our 3D printing and 3D modeling articles here at the MakerHub.